Application Of Different Types Of Heat Exchangers In Dairy And Food Industry

What are the Different Types of Shell and Tube Heat Exchangers. Heat exchangers for the food and dairy industries are used in thousands of facilities in the USA Canada and Mexico.

Heat Exchanger Advantages Uses And Applications Sacome

Heat Exchanger Advantages Uses And Applications Sacome

Direct Contact Heat Exchangers.

Application of different types of heat exchangers in dairy and food industry. In this blog we describe plate and frame shell and tube and scraped surface heat exchangers used in food beverage dairy and pharmaceutical processing. This article elucidates the application of different types of heat exchangers in the bioprocess industry. It is also used for short-term heating heating and cooling of desserts ice-cream mixes cream and yogurt.

The heat exchangers are employed in the dairy and food industry continuously for pasteurizing the milk without using maximum energy. Applications of Various Heat Exchangers 1. With our extensive spectrum of heat exchangers we offer the dairy processing industry integrated solutions for their entire added-value process beginning with cooling of freshly milked milk including pasteurization and.

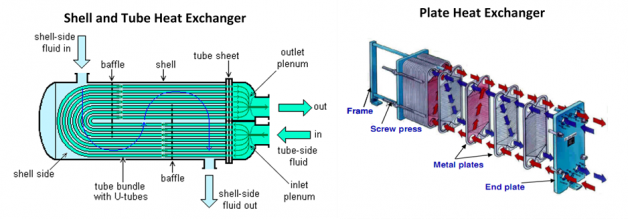

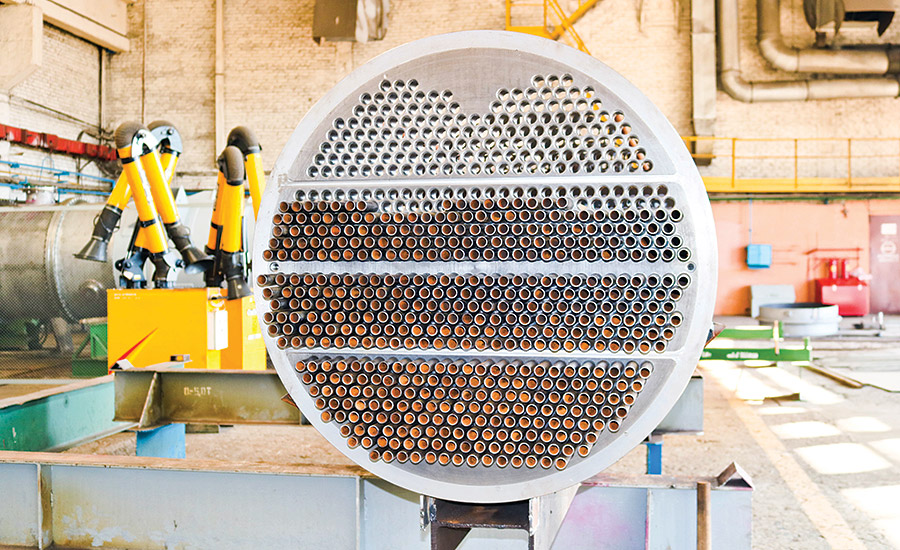

Tubular heat exchanger Scraped-surface heat exchanger. Each type has its own set of features pros and cons. There is a wide range of shell and tube heat exchangers available across the market.

Each 3-A compliant exchanger offers sanitary connections on the process side. The result for many producers is a highly complex portfolio with products such as fresh milk for drinking ultra-high-temperature milk UHT milk butter cream yoghurt cheese and quark concentrates baby food and Greek yoghurt loved not only in the USA. The main advantage is the gentle handling which maintains the key viscosity characteristics of the product such as texture and mouth-feel.

Since then plate heat exchangers have assumed a predominant role for heating and cooling purposes in the dairy industry. While several types of heat exchangers are used in the food industry Fryer says that the most common are plate heat exchangers. Our heat exchangers comply with 3-A and BPE standards for heating or cooling WFI milk products and foods.

Plate heat exchangers have been around for a long time she says. Dairy plants most often use plate heat exchangers noted Anders Nelson design engineer at OBrien Gere Syracuse NY a systems integrator and certified member of the Control System Integrators Association CSIA. Plate heat exchangers Another popular heat exchanger for fluids of low viscosity such as milk is the plate heat exchanger where heating and cooling fluids flow through alternate tortuous passages between vertical plates as illustrated in figure 2.

This includes the processing of liquids creams and yogurts warming of syrups melting of chocolate production of whey protein concentrate as well as many other processes. Heat exchanger types vary to meet requirements for processing efficiency cost of ownership and maintenance. In addition SIGMA plate heat exchangers are used today for a whole series of heating cooling and heat-exchange procedures in the dairy economy.

Dairy food and beverage manufacturers operate in a highly competitive environment with a need to deliver safe hygienic and tasty food at competitive prices while having a minimal impact on the environment. The application of heat exchangers in bioprocess industry varies over a wide range from the thermal treatment of fluid foods to the concentration of juices to the cooling of stirred yoghurt or freezing of liquids. Gasketed plate heat exchanger.

Plate and frame heat exchanger. A typical milk process for instance will have a large plate and frame heat exchanger for pasteurizing while operators may use a dynamic scraped-surface heat exchanger for spray drying cheese due to the high percentage of solids says Trent Bullock CSI manager engineering services. Theyre one of the most efficient methods of heat transfer for fluid products.

The specialized plate heat exchangers perform several tasks including cooling short-term heating and heating of milk. But there are many other benefits from using tubular heat exchangers in the dairy sector. Enerquips heat exchangers are used in thermal systems for many heating and cooling applications in the food and dairy industry.

SIGMA plate heat exchangers as multi-sectioned units with serveral thermal requirements have been employed in the dairy sector for the first time to achieve a longer stability of milk. It is required in the process of heating or cooling of fluid foods. The following three types of heat exchangers are the most widely used nowadays.

PCV Platular heat exchanger. Operators may choose from three different types of heat exchangers typically based on the mix of products they have in mind. In the production of Chocolate peanut butter Fudges Spreads Mayonnaise and other viscous products Heat exchangers are used.

Shell and coil heat exchanger. Shell and Tube Heat Exchanger Food Beverage and Dairy MarineNavy Air Processing Compressor Cooling ChemicalPetrochemical Processing Refining Pharmaceuticals Power and Electricity generation Metals and Mining Refrigeration Pulp Paper 15. Heat exchangers find application not only in the food and dairy industry but also in pharmaceutical.

The use of heat exchangers in the bioprocess industry is inevitable. HRS Heat Exchangers provide a range of heat exchangers components modules and complete processing systems that help you to optimize production make the most of raw materials while reducing energy consumption waste and emissions. Here are some common types of shell and tube heat exchangers which are popular in different industries.

It is also being applied in cryogenic processes sterilization techniques and production of ethanol. The heat exchangers also utilize for cooling of brine curb and super-heating process of cream. Platular smart hybrid welded plate heat exchanger.

In Production of Juice sauce edible oil syrup and Soup industry Heat exchangers play a major role In the process Evaporation with the help of Heat exchangers is used to increase sugar concentration in the product. Brazed plate heat exchanger. Shell and tube heat exchanger.

And the evaporation freezing or crystallization of liquids for the manufacture of sorbet ice creams and juices. Using tubular heat exchangers can provide a number of benefits for viscous dairy products.

Applications Of Heat Exchangers In Chemical Industry Worldofchemicals

Applications Of Heat Exchangers In Chemical Industry Worldofchemicals

Food Dairy Different Type Of Heat Exchangers

Food Dairy Different Type Of Heat Exchangers

The Latest In Heat Exchangers For Food Processing Process Expo 2021

The Latest In Heat Exchangers For Food Processing Process Expo 2021

Food Dairy Different Type Of Heat Exchangers

Heat Exchanger The Ultimate Faq Guide Filson Filter

Heat Exchanger The Ultimate Faq Guide Filson Filter

%2018.05.40.png?width=1358&name=Captura%20de%20pantalla%202018-07-09%20a%20la(s)%2018.05.40.png) Heat Exchanger Uses In Metal Industry

Heat Exchanger Uses In Metal Industry

4 Types Of Heat Exchangers Zwirner Equipment

4 Types Of Heat Exchangers Zwirner Equipment

Proquip Solutions Heat Exchangers Dryers Evaporators

Proquip Solutions Heat Exchangers Dryers Evaporators

The Hidden Costs Of Plate Heat Exchangers In The Food Industry

The Hidden Costs Of Plate Heat Exchangers In The Food Industry

Heat Exchangers An Overview Sciencedirect Topics

Heat Exchangers An Overview Sciencedirect Topics

Heat Exchanger Types And Selection

Heat Exchanger Types And Selection

Food Dairy Different Type Of Heat Exchangers

Understanding Heat Exchangers Types Designs Applications And Selection Guide

Understanding Heat Exchangers Types Designs Applications And Selection Guide

Milk Fouling In Heat Exchangers Heat Exchanger World

Milk Fouling In Heat Exchangers Heat Exchanger World

Selecting The Best Heat Exchanger For Dairy Pasteurization 2018 03 09 Dairy Foods

Selecting The Best Heat Exchanger For Dairy Pasteurization 2018 03 09 Dairy Foods

Plate Heat Exchanger How It Works Working Principle Hvac Industrial Engineering Phx Heat Transfer Youtube

Plate Heat Exchanger How It Works Working Principle Hvac Industrial Engineering Phx Heat Transfer Youtube

Selecting A Process Heat Exchanger For Your Application Api Heat Transfer

Selecting A Process Heat Exchanger For Your Application Api Heat Transfer

Food Dairy Different Type Of Heat Exchangers